DGX SERIES ISOBARIC WASHING/FILLING/CAPPING MONOBLOCK

APPLICATION

his series equipment is used to produce all kinds of carbonated drink contained in PET bottle. Washing, filling, and cap-pingcan be carried out on this machine. This machine has the following characteristics: scientific and reasonable design, bea-utiful appearance, complete function, convenient maintenance, and high automation.

FEATURES

(1) The suspending bottle-necks cramping design makes the whole production line more stable during the working process and it also avoids malfunctions caused by the differences ofthickness and height of the bottle. This design also dramatically reduces the required numberof changeable parts, makes it more convenient to change the types of bottles.

(2) The advanced technologies from Germany and Italy are introduced. Isobaric filling technology is used in this machine. Filling is quick and the amount of the liquid can be controlled accurately. Also, the beverage-holding tank is fully-closed and the CIP in-terface is installed.

(3) Magnetic torque is used for screw capping, and the power of screw capping can be adjusted steplessly. It can use constant power to screw the plastic caps and will not damage the caps.

(4) Horizontal swirl wind-power cap-managing device is used to avoid damaging the surface of the cap. And when there is shortage of caps in the caps storage tank, caps will be fed automatically.

(5) Human-machine interface touch-screen is adopted in this machine. The liquid level in the tank can be controlled automatically.The filling and capping will stop automatically when there is no bottle.

(6) All parts that have direct contact with the beverages are made of high quality stainless steel. And the main electrical components are from famous international companies.

MAIN TECHNICAL STANDARDS

|

Model |

DGX-14-12-5 |

DGX-18-18-6 |

DGX24-24-6 |

DGX32-32-8 |

DGX40-40-10 |

DGX60-50-15 |

|

Production Capacity(bph)(500ml) |

2000-3000 |

4000-5000 |

6000-8000 |

9000-11000 |

12000-14000 |

16000-18000 |

|

Filling Pressure(Mpa) |

≤0.4 |

|

Applicable Bottle Type |

Bottle DiameterΦ50-Φ100mm;Height150-320mm;Volume330-1500ml |

|

Applicable Cap Shape(Mpa) |

Plastic Screw Cap |

|

Gas Source Pressure(Mpa) |

0.6 |

|

Gas Consumption(m3/min) |

0.2 |

0.3 |

0.4 |

0.5 |

0.55 |

0.6 |

|

Total Power(kw) |

4.6 |

5.03 |

6.4 |

8.07 |

9.56 |

11.18 |

|

Total Weight(kg) |

2500 |

4200 |

5800 |

7000 |

9000 |

12000 |

|

Dimension(L*W*H)(mm) |

2350*1700*

2150 |

2830*2030*

2030 |

3220*2400*

2600 |

3450*2510*

2710 |

3800*2800*

2710 |

4510*3400*

2900 |

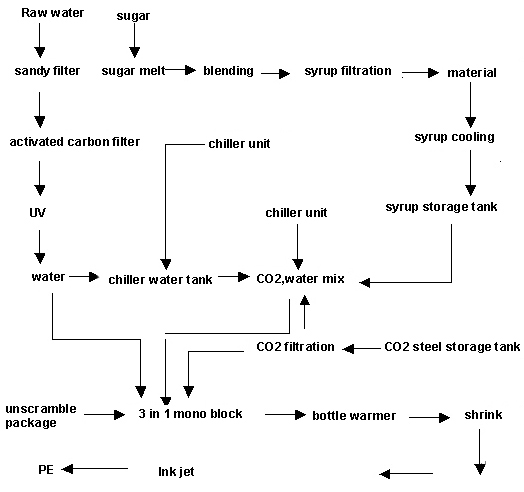

Carbonated Filling Line Flow Chart

|